Overview of the CompTIA 220-1101 Exam

The CompTIA 220-1101 exam is a crucial certification for IT professionals seeking to validate their knowledge of hardware, networking, and troubleshooting various technological issues. This exam is part of the CompTIA A+ certification series, which is recognized globally as a foundational credential for IT technicians. The 220-1101 exam focuses on mobile devices, networking technology, hardware, virtualization, and cloud computing, making it essential for individuals aiming to build a career in IT support and administration.

The 220-1101 exam tests candidates on their ability to install, configure, and troubleshoot various devices, including thermal printers. Understanding the principles and maintenance of thermal printers is a key aspect of the exam, as these printers are widely used in various industries such as retail, healthcare, and logistics.

Definition and Working Principle of Thermal Printers

A thermal printer is a type of printer that uses heat to produce images on paper. Unlike inkjet or laser printers, thermal printers do not use ink or toner cartridges. Instead, they rely on heat-sensitive paper (thermal paper) or a ribbon to generate prints.

There are two main types of thermal printers:

-

Direct Thermal Printers – These printers use chemically treated paper that changes color when exposed to heat. They do not require ink or ribbons, making them cost-effective for short-term use, such as receipts and shipping labels.

-

Thermal Transfer Printers – These printers use a ribbon coated with ink that melts onto the printing surface when heated. This method provides durable and high-quality prints suitable for barcodes, labels, and long-term documentation.

Thermal printers operate by applying heat to specific areas of the paper or ribbon through a print head. The print head contains a series of small heating elements that activate in response to electrical signals, creating an image or text on the paper. Due to their speed, efficiency, and low maintenance, thermal printers are preferred in environments that require fast and reliable printing solutions.

Factors Affecting the Life of a Thermal Printer

Several factors influence the lifespan of a thermal printer, including:

-

Print Head Durability – The print head is a crucial component and is subject to wear and tear over time.

-

Quality of Paper and Ribbons – Using low-quality thermal paper or ribbons can damage the print head and reduce print quality.

-

Environmental Conditions – Dust, humidity, and temperature fluctuations can affect the printer's performance and longevity.

-

Usage Frequency – Frequent use without proper maintenance can lead to faster deterioration of components.

-

Firmware and Software Updates – Outdated firmware or drivers can cause malfunctions and compatibility issues.

By addressing these factors, users can significantly extend the lifespan of their thermal printers.

Best Practices to Extend the Life of a Thermal Printer

To ensure optimal performance and longevity of a thermal printer, it is essential to follow best practices for maintenance and usage.

Regular Cleaning and Maintenance

Routine cleaning is vital to prevent dust and debris buildup on the print head and rollers. Use a lint-free cloth and isopropyl alcohol to gently clean the print head and remove any residue. Additionally, ensure that internal components, such as rollers and sensors, are free from dust accumulation.

Using High-Quality Thermal Paper and Ribbons

Investing in high-quality thermal paper and ribbons can prevent print head damage and improve print clarity. Inferior materials can leave behind residue that clogs the print head, leading to poor print quality and frequent maintenance issues.

Avoiding Overheating Issues

Thermal printers generate heat during operation, and excessive heat can damage the print head. To prevent overheating:

-

Ensure proper ventilation around the printer.

-

Avoid prolonged high-speed printing.

-

Allow the printer to cool down after extended use.

Proper Handling and Storage

Handle the printer with care to prevent physical damage. Store thermal paper in a cool, dry place to prevent premature discoloration and degradation. Ensure that the printer is kept away from direct sunlight and extreme temperatures.

Regular Firmware and Driver Updates

Manufacturers frequently release firmware and driver updates to improve performance and fix known issues. Keeping the printer’s software up to date ensures compatibility with operating systems and enhances overall functionality.

Common Mistakes That Reduce Printer Lifespan

Many users unknowingly make mistakes that can shorten the life of their thermal printers. Some of the most common errors include:

-

Using Low-Quality Supplies – Cheap thermal paper and ribbons can damage the print head and reduce print quality.

-

Neglecting Regular Maintenance – Failing to clean the printer regularly leads to dust accumulation and poor performance.

-

Overusing the Printer Without Breaks – Continuous high-speed printing can cause overheating and premature wear.

-

Ignoring Error Messages – Not addressing warning messages or malfunctions can lead to irreversible damage.

-

Skipping Firmware Updates – Running outdated software can cause compatibility and functionality issues.

Avoiding these mistakes can significantly increase the lifespan and efficiency of a thermal printer.

Troubleshooting Common Thermal Printer Issues

Thermal printers may experience various issues over time. Here are some common problems and their solutions:

-

Faded or Light Prints – Check the print head for dirt or residue and clean it with a soft cloth and alcohol.

-

Paper Jams – Ensure that the paper is properly loaded and that there are no obstructions in the paper path.

-

Print Head Not Heating Properly – Verify that the printer is receiving the correct voltage and that the print head is clean.

-

Lines or Streaks on Prints – This may indicate a damaged or dirty print head. Cleaning or replacing the print head can resolve the issue.

-

Connectivity Issues – Ensure that all cables are securely connected and that the drivers are up to date.

If problems persist, consulting the manufacturer’s manual or seeking professional assistance can help resolve complex issues.

Conclusion

Thermal printers are essential tools in various industries, providing fast and efficient printing solutions. Understanding their working principles, factors affecting their lifespan, and best maintenance practices can help users maximize their efficiency and durability.

By following recommended maintenance routines, using high-quality supplies, and avoiding common mistakes, users can extend the life of their thermal printers and ensure consistent performance. Additionally, staying updated with firmware and troubleshooting common issues promptly can prevent costly repairs and downtime.

For those preparing for the CompTIA 220-1101 exam, having a solid understanding of thermal printers and their maintenance is crucial. DumpsBoss provides comprehensive study materials and practice tests to help candidates successfully pass the exam and advance their IT careers. Investing time in learning these concepts not only enhances exam performance but also prepares individuals for real-world troubleshooting and technical support roles in the IT industry.

Special Discount: Offer Valid For Limited Time “220-1101 Exam” Order Now!

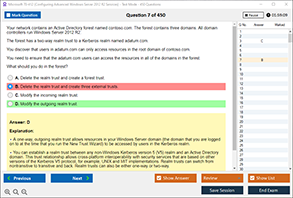

Sample Questions for CompTIA 220-1101 Dumps

Actual exam question from CompTIA 220-1101 Exam.

How can the life of a thermal printer be extended?

A. Use low-quality paper to reduce costs

B. Regularly clean the printhead and use high-quality thermal paper

C. Keep the printer in a humid environment

D. Avoid using the printer frequently