Overview of the GAQM CLSSGB Exam

The GAQM Certified Lean Six Sigma Green Belt (CLSSGB) exam is a prestigious certification that evaluates a professional's ability to apply Six Sigma principles and tools to improve business processes. Six Sigma, an established methodology for process improvement, is valued worldwide across various industries for its ability to identify and eliminate inefficiencies, enhance quality, and drive customer satisfaction.

To earn the CLSSGB credential, candidates need to demonstrate proficiency in the key concepts of Lean Six Sigma, including problem-solving techniques, data analysis, and process management strategies. The exam itself is structured to test both theoretical knowledge and practical application, ensuring that candidates are ready to take on roles where they can contribute significantly to an organization’s performance improvements.

While the importance of Six Sigma in the corporate world cannot be overstated, there are several misconceptions about the methodology that can hinder its successful implementation. In this article, we will explore common myths surrounding Six Sigma and address the truth behind them, particularly in relation to the GAQM CLSSGB certification.

Definition and Core Principles of Six Sigma

Before diving into the misconceptions, it’s crucial to understand what Six Sigma is and why it matters.

Six Sigma is a set of techniques and tools aimed at improving processes by identifying and eliminating defects and variability. Its primary goal is to achieve near-perfect processes, defined as producing fewer than 3.4 defects per million opportunities. This rigorous standard is intended to elevate product quality, customer satisfaction, and operational efficiency.

The methodology consists of two key approaches:

- DMAIC (Define, Measure, Analyze, Improve, Control) – Used for improving existing processes.

- DMADV (Define, Measure, Analyze, Design, Verify) – Used for creating new processes or products.

Six Sigma uses statistical tools and methods, including process mapping, hypothesis testing, and control charts, to identify areas for improvement and implement changes that result in measurable improvements.

Common Misconceptions of Six Sigma

Although Six Sigma is a valuable methodology, many organizations and individuals still harbor misconceptions that prevent them from fully embracing its potential. Here, we will address the top misconceptions about Six Sigma and provide clarity on each one.

Misconception 1: Six Sigma is Only for Large Companies

One of the most prevalent misconceptions about Six Sigma is that it is only suitable for large organizations with vast resources. This idea stems from the misconception that Six Sigma requires significant investments in training, tools, and expertise that only large enterprises can afford.

In reality, Six Sigma is highly versatile and can benefit organizations of all sizes. Small and medium-sized enterprises (SMEs) can use Six Sigma to streamline operations, reduce waste, and improve quality, often leading to cost savings and enhanced customer satisfaction. For instance, small businesses can implement Six Sigma tools on a smaller scale, focusing on specific areas that need improvement without requiring a large-scale implementation.

The CLSSGB exam, offered by GAQM, is designed to equip professionals with the knowledge to apply Six Sigma methods to any organization, regardless of size. So, whether you're working in a multinational corporation or a small startup, Six Sigma principles can be adapted to suit your business needs.

Misconception 2: Six Sigma is Only for Manufacturing Industries

Another common misconception is that Six Sigma is only relevant to manufacturing industries. Historically, Six Sigma began in manufacturing settings, particularly in companies like Motorola and General Electric, which drove its adoption. However, over the years, Six Sigma has proven to be highly adaptable and valuable across a wide range of industries, including healthcare, finance, IT, education, and service sectors.

The application of Six Sigma is not confined to the production floor. In the healthcare sector, for example, Six Sigma methodologies have been used to reduce patient wait times, improve patient outcomes, and streamline administrative processes. In finance, Six Sigma is used to optimize processes related to transaction handling, customer service, and risk management.

Thus, regardless of your industry, the principles taught in the CLSSGB exam can be applied to help solve challenges and improve performance in a wide range of environments.

Misconception 3: Six Sigma is About Perfection

Many people misunderstand Six Sigma as a methodology that aims to achieve "perfection." While it’s true that Six Sigma strives for extremely high levels of quality (3.4 defects per million opportunities), the goal is not to create a flawless system or process. Instead, the focus is on significantly reducing errors and inefficiencies in processes and ensuring that improvements are sustainable over time.

The goal of Six Sigma is to reach a level of quality where processes are predictable, reliable, and capable of meeting customer requirements. This is achieved through continuous improvement, where data is used to identify areas for enhancement and solutions are implemented to reduce defects. It is important to note that Six Sigma recognizes that not all variables can be controlled, and striving for perfect quality can sometimes be unrealistic and unnecessary.

In the context of the GAQM CLSSGB exam, candidates are taught how to measure process variation, analyze root causes, and implement controls to maintain high-quality outcomes, not to achieve absolute perfection.

Misconception 4: Six Sigma is Too Complicated and Difficult to Implement

Another myth surrounding Six Sigma is that it is an overly complex methodology that is difficult to implement and requires specialized expertise. This belief may discourage organizations from adopting Six Sigma practices and prevent employees from pursuing certification.

While it’s true that Six Sigma involves statistical analysis and data-driven decision-making, the methodology is structured in a way that makes it manageable for professionals at all levels. The DMAIC and DMADV frameworks break down the process into clear, systematic steps, and various tools are available to assist in problem-solving and process improvement.

Moreover, the GAQM CLSSGB exam provides candidates with the foundational knowledge required to implement Six Sigma in a straightforward manner. The certification program ensures that professionals learn the core concepts, tools, and techniques needed to make tangible improvements in processes without feeling overwhelmed by complexity.

Six Sigma implementation can be scalable, meaning it can be adapted to fit the size and complexity of the problem. Whether you are implementing it for a small process change or for a company-wide initiative, Six Sigma offers flexible solutions that are not inherently difficult to grasp or apply.

The Correct Answer (Not a Common Misconception)

The correct view is that Six Sigma is a universally applicable methodology for improving processes across industries of all sizes. By focusing on reducing variability, improving quality, and increasing efficiency, Six Sigma provides organizations with a structured, data-driven approach to problem-solving. Its principles can be implemented in any industry, whether large or small, and can be customized to meet the unique needs of a business.

Six Sigma is also not about striving for perfection but rather about continuous improvement. The idea is to identify areas for improvement, implement changes that lead to quantifiable results, and make adjustments as necessary. Furthermore, Six Sigma is designed to be accessible, with training and certification opportunities, such as the GAQM CLSSGB, that equip professionals with the knowledge and skills to drive improvements without requiring extensive expertise upfront.

Impact of Misconceptions on Six Sigma Implementation

Misconceptions about Six Sigma can have a significant impact on its adoption and successful implementation within an organization. When employees or decision-makers believe that Six Sigma is only for large companies, limited to manufacturing, or too complex to implement, they may avoid exploring it as a potential solution. This reluctance can lead to missed opportunities for process improvement, cost reduction, and enhanced customer satisfaction.

By dispelling these myths and providing the correct understanding of Six Sigma, organizations can more effectively harness its potential to drive positive change. Furthermore, pursuing certification like the GAQM CLSSGB exam helps professionals gain the confidence and expertise needed to lead Six Sigma initiatives and contribute to organizational success.

Conclusion

The GAQM CLSSGB exam is an invaluable certification for professionals seeking to master Six Sigma principles and contribute to business process improvements. Unfortunately, several misconceptions about Six Sigma persist, including the beliefs that it is only for large organizations, limited to manufacturing industries, focused on achieving perfection, or overly complicated.

By addressing these myths and understanding the true nature of Six Sigma, professionals and organizations can better appreciate its value and the benefits it offers. Six Sigma is a powerful, adaptable methodology that, when implemented correctly, can lead to significant improvements in efficiency, quality, and customer satisfaction. With the right training and a clear understanding of the methodology, such as that provided by the GAQM CLSSGB exam, anyone can become a key player in driving process improvement in their organization.

Special Discount: Offer Valid For Limited Time “CLSSGB Exam” Order Now!

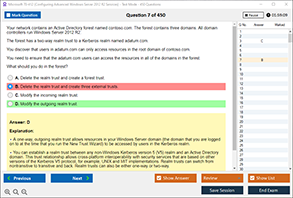

Sample Questions for GAQM CLSSGB Dumps

Actual exam question from GAQM CLSSGB Exam.

Which of the following is not a common misconception of the Six Sigma methodology?

A) Six Sigma is only for large companies.

B) Six Sigma is a one-time project.

C) Six Sigma focuses solely on reducing defects.

D) Six Sigma is only for the manufacturing industry.